Engineering is a highly practical and hands-on field that demands a thorough knowledge of the technical equipment for engineering education. From delicate lab instruments to complex industrial machinery, having access to cutting-edge equipment is critical for aspiring engineers to acquire practical skills and knowledge that they can apply in real-world situations.

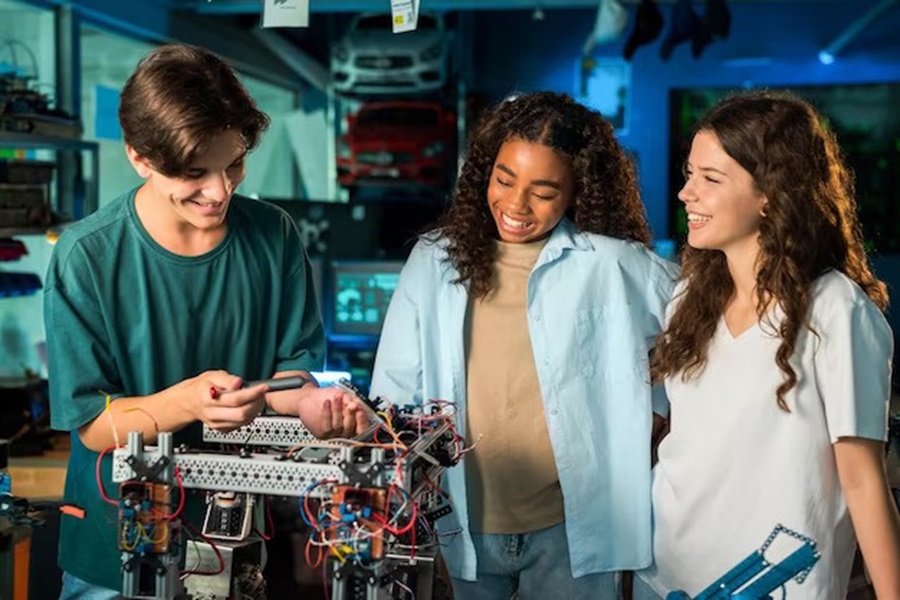

As engineering students advance in their studies, they get to work with a diverse range of equipment, which not only reinforces their theoretical understanding but also prepares them for the challenges they may face in their future careers. By gaining hands-on experience with various tools and technologies, students can develop a deep understanding of the principles and concepts that underpin their field, and become better equipped to tackle complex engineering problems with confidence and expertise.

Why Equipment Matters in Engineering Education

There are several key reasons why equipment accessibility and training are so important for engineering students:

Developing Hard Skills

Working with real equipment is the only way for students to gain proficiency in using the technology and tools needed in engineering roles. This hands-on experience builds the hard skills they will rely on daily in their future jobs. Whether it’s learning to operate drilling rigs in petroleum engineering or use oscilloscopes in electrical engineering, physical equipment provides an applied context for theoretical lessons.

Understanding Real-World Applications

Seeing how equipment is used for practical applications of engineering gives students insight into how their field operates in the real world. For example, chemical engineering students who run experiments using pilot plant reactors learn about scaling up lab bench processes to industrial levels. Interacting with equipment, including automotive mechanical engineering units, in an educational setting prepares them for the types of machinery found in plants and facilities.

Reinforcing Theoretical Principles

Hands-on practice using equipment and instrumentation reinforces the engineering science concepts students study in lectures and textbooks. Measuring pressure in a pipeline, testing material strength, or analyzing circuit outputs lets students see theory come to life. Performing experiments validates their knowledge and improves comprehension of complex technical concepts.

Developing Troubleshooting Skills

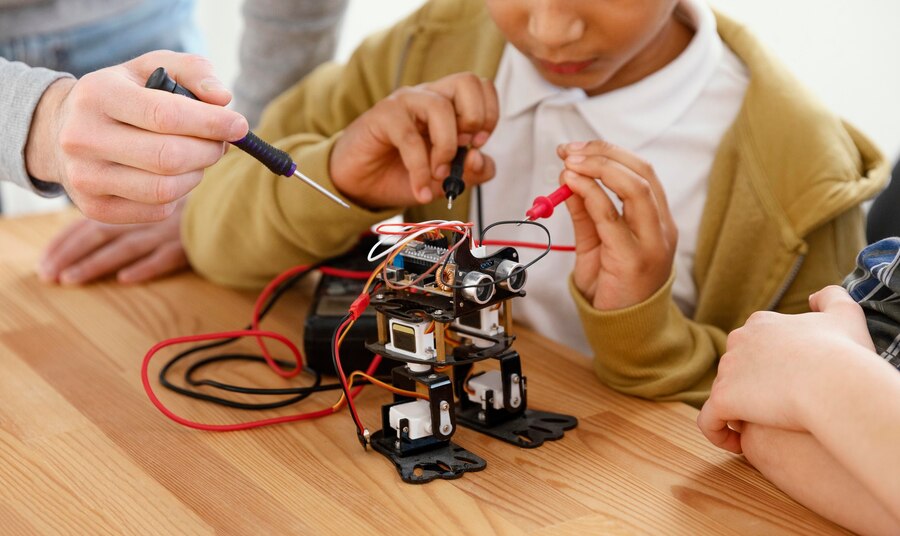

Things don’t always go perfectly when running tests with sensitive equipment and complex machinery. Engineering students get valuable experience identifying and troubleshooting issues. Diagnosing equipment glitches requires critical thinking and teaches problem-solving methods. Being able to quickly resolve problems with tools and technology is an invaluable skill in any engineering role.

Learning Safety Procedures

Operating powerful industrial equipment comes with serious safety risks. Engineering programs emphasize proper safety protocols when working in labs or interacting with machinery. Students who learn to follow rig safety checklists, wear PPE, and identify hazards gain awareness they will carry throughout their careers. Respect for equipment safety is a foundational element of being an engineer.

Gaining Confidence

Working with intimidating equipment like lathes, CNC machines, robots, and laser cutters initially requires courage. As engineering students become proficient operating equipment, it boosts their self-assurance and sense of capability. This confidence will help them excel in technical roles after graduation. Early hands-on experiences also build enthusiasm for entering their engineering field.

Overall, integrating equipment into engineering education allows students to transition smoothly into professional roles. Both theoretical knowledge and practical abilities are required to become successful engineers.

Key Equipment Used in Major Engineering Disciplines

The type of equipment engineering students get experience with depends on their particular field of study:

Mechanical Engineering

- Machine shop tools (lathes, mills, drill presses, grinders)

- Metrology instruments (micrometers, calipers, gauges)

- 3D printers/rapid prototyping equipment

- Robotics/automation systems

- Materials testing instruments (tensile testers, hardness testers)

- CNC machining centers

- Vibration/motion analysis systems

- Project vehicles/engines for competitive teams

Electrical Engineering

- Oscilloscopes, function generators, power supplies

- Circuit simulation software

- Breadboards, wire wrap boards

- Logic analyzers, multimeters

- Robotic kits -PLC (programmable logic controller) trainers

- Solar panels, batteries, inverters

Chemical Engineering

- Bench and pilot plant reactors

- Distillation columns, evaporators

- Process instrumentation (temp/pressure/flow sensors)

- Heat exchangers, boilers

- Mixing vessels, fermenters

- Analytical lab instruments (GC, HPLC, spectrophotometers)

Civil/Structural Engineering

- Structural testing apparatuses (for beams, concrete, steel, soils)

- Surveying equipment

- Material analyzer machines (for steel, cement, aggregate)

- BIM/CAD software for drafting

- GPS surveying tools

- Wind tunnels, shake tables

Industrial/Manufacturing Engineering

- CNC machines, 3D printers

- PLCs, robotics

- Supply chain/logistics simulation software

- Time and motion tools

- Ergonomics assessment apparatuses

- Facilities planning programs

- Quality inspection tools

Biomedical Engineering

- Medical imaging devices

- Surgical robots

- Biomaterials testing equipment

- Microscopes, cell culture lab tools

- Biomedical instrumentation for signals

- Prosthetics and wearables

- Telemedicine systems

This list highlights the diversity of equipment students get to use through lab courses and hands-on learning. Gaining proficiency operating these machines and tools prior to entering industry gives graduates an advantage.

Strategies for Incorporating Equipment into Curriculum

Engineering schools employ various methods to integrate hands-on equipment experiences into their programs:

Lab Courses

Dedicated on-campus lab courses enable students to learn equipment alongside technical concepts from lectures. Labs are designed to align with major courses covering topics like circuits, materials science, fluid mechanics, and more. Sessions include training on equipment operation and safety, performing technical experiments, and analyzing data. Lab courses encourage self-directed learning and build skills for conducting engineering tests.

Accessible Equipment Rooms

Having rooms with equipment students can freely access outside of scheduled labs provides critical extra practice time. Machines like 3D printers, CNC mills, soldering irons, measurement tools allow students to work on personal projects that interest them and develop creative applications for equipment. Extra experience boosts confidence.

Capstone Senior Projects

A culminating senior capstone challenges students to apply all their skills to an independent project. Students utilize equipment relevant to their focus area to construct prototypes, make tools, or run experiments. With mentor guidance, they problem-solve real issues. Capstones give students freedom to direct their learning while using equipment creatively.

Student Competitions

For hands-on experience beyond the classroom, schools often support student teams that compete in national design competitions. Events like Formula SAE and Boeing Blue Sky allow students to gain intensive training designing, building, testing, and troubleshooting complex vehicles, robots, and functional prototypes. The experience is invaluable preparation for engineering careers.

On-Campus Job Training

Job opportunities like lab technicians and machine shop monitors allow students to informally teach peers equipment skills. The experience of running equipment demos, supervising safety, performing maintenance, and assisting with projects cements technical knowledge. These roles often continue into paid on-campus jobs after graduation.

Internships & Co-ops

Off-campus internships and co-ops at technology companies provide access to professional equipment that schools can’t provide. Working alongside engineers, students gain hands-on training on industry-grade manufacturing machines, test instruments, and analysis tools they will encounter working in the field.

Facility Tours

Job site trips to manufacturing plants, materials labs, and engineering firms allow students to see working equipment. Tours of facilities like power plants, semiconductor factories, and construction sites showcase the scale of real-world equipment. Site visits inspire students by revealing possible career paths.

Overall, a combination of lab work, student projects, job experiences, and facility tours ensures graduates have significant preparation operating equipment.

Challenges Facing Engineering Schools

While hands-on learning is clearly vital for engineers’ success, many schools face roadblocks providing sufficient equipment experiences:

Budget Constraints

The high cost of purchasing and maintaining state-of-the-art equipment prevents some universities from adequately outfitting labs and project spaces. Without budgets for the latest measurement tools, prototyping machinery, analytical software, and computers, students lack access. Some resort to simulations only.

Limited Lab Time

Heavy course loads and staffing limits mean lab courses are often only 1-2 hours per week. This provides minimal time for each student to have hands-on equipment practice compared to lecture theory. Students would benefit from more open lab hours without rigid scheduling.

Insufficient Support Staff

Properly supervising lab equipment use requires trained support staff. Schools with inadequate lab managers, instructional technicians, and student tutors cannot facilitate sufficient use of machines. Lack of maintenance also causes reliability issues.

Rapidly Advancing Technology

Lab devices and machines become outdated quickly as technology progresses. Schools struggle keeping curriculum continuously updated with limited budgets. Graduates who trained on old equipment may lack skills on new tools used in industry. Partnerships with companies could help.

Space Limitations

Available classroom and lab square footage restricts how much equipment engineering departments can install. Complex machinery like manufacturing tools need dedicated spaces that many campuses lack. There are tradeoffs between quantity of equipment and number of students accommodated.

Safety Hazards

Labs handling flammable chemicals, high voltages, or mechanical hazards add liability risks and require significant safety management. Universities must weigh dangers of experiments against educational rewards. This limits student access to certain equipment. Culture of safety is paramount.

Lack of Hands-On Experience Among Instructors

Professors who come from pure research backgrounds without industry experience may not value hands-on curriculum. They often prioritize theory over equipment skills. This reduces student equipment usage. Schools should encourage hands-on professional development among faculty.

These constraints make it difficult for schools to deliver optimum equipment-centered learning. However, expanding partnerships with private companies could help schools provide augmented learning experiences.

Partnerships with Industry to Enhance Hands-On Learning

To overcome equipment challenges, engineering schools are collaborating with the private sector in innovative ways:

Donated Machines & Technology

Industry partners can donate state-of-the-art machinery, instruments, and computers to replace aging lab equipment. Companies benefit by training students on their technology. The latest tools excite students and better prepare them for real-world settings. However, maintenance costs may still burden schools.

Sponsored Capstone Projects

Companies provide funding, expertise, and equipment access for senior capstone projects related to current industry problems. Students get to use facilities they couldn’t access otherwise. Company engineers act as mentors. Firms benefit from fresh ideas and talent recruitment.

Use of Commercial Facilities

Some schools partner with factories, plants, and research campuses to utilize their test facilities for specialized lab sessions. Students gain training on equipment unavailable at their campus. Facilities can also provide student co-op experiences.

Guest Instruction from Industry Experts

Training students directly on machinery can be provided by qualified guest instructors from partner companies. On-site field engineers and technical experts give introduction to advanced equipment. This insight helps students understand how tools are used in businesses.

Remote Lab Access

Using telepresence robots and virtual reality, students can remotely access and perform experiments on equipment at different locations. Companies can keep proprietary tools on-site while allowing remote operation. This expands possibilities for valuable lab experiences.

Certification Training Programs

Corporate-sponsored seminars and certification courses on campus provide focused training on specific instruments or machines. Students certified gain advantage in the job market. Companies connect to top talent.

Equipment Leasing Options

Some vendors lease equipment to schools short-term rather than forcing capital purchases. This allows access to expensive modern tools while costs are shared. Leasing also includes technical support and upgrades from the vendor. New equipment can be rotated in as technology changes.

Idea Incubator Spaces

Corporate partners can establish innovation spaces on campus for collaborative student projects using industry tools and oversight. Teams develop concepts and prototypes to solve real business problems. Companies get creative solutions while guiding young talent.

Overall, creative public-private partnerships provide engineering students supplemental avenues to hone hands-on abilities. Industry plays a huge role in nurturing the next generation of technical workers.

Promising Directions for the Future

Engineering educators are actively adapting their programs to place greater emphasis on equipment skills. Some promising directions include:

- Seeking alternative funding sources for upgraded tools like grants, sector partnerships, industry alliances, and alumni donations.

- Adding more project-based courses where access to equipment is central rather than traditional theory lectures.

- Investing in rapid prototyping tools like 3D printers, electronics workstations, and CNC machines that support realizing student ideas.

- Developing more remote and virtual lab interfaces to maximize equipment usage time among larger student populations.

- Making equipment-focused training a priority for both students and faculty through on-site industry co-ops.

- Considering leasing and shared use options to acquire costly machinery and software that would be otherwise unaffordable.

- Having more industry advisory panels guide curriculum design to ensure programs align with skills needed in the field.

- Giving students equipment references and recommendations to purchase for personal ownership. Building small home labs and projects encourages self-directed learning.

- Expanding makerspaces, project garages and design studios for students to creatively practice hands-on engineering skills beyond formal labs.

By making equipment accessibility a strategic priority, engineering programs can remain relevant and continuously adapt teaching methods to support student success.

Frequently Asked Questions

Q: Why can’t engineering students just gain equipment experience after they are hired, rather than in school?

A: Companies expect new engineering graduates to arrive with baseline proficiency operating lab instruments, manufacturing machines, test tools, and simulation software used in the field. Learning on the job is expensive for employers. Students who lack hands-on exposure are disadvantaged entering industry.

Q: Should engineering students join extracurricular project teams to gain more equipment skills?

A: Student teams designing robots, race cars, rockets, and other complex projects provide excellent supplementary hands-on training. However, these clubs shouldn’t replace integrated classroom equipment experiences which all students need to access. Project teams do allow extended use of machinery.

Q: What is the ideal balance between theoretical education and equipment training in engineering curriculums?

A: Most educators agree that curriculums should be weighted approximately 60% hands-on application using equipment and 40% classroom theory. However, some theoretical topics warrant more time, while others pair well with extended equipment labs. Schools must find the right program balance.

Q: How can schools with limited budgets keep their equipment updated?

A: With rapid technology advances, labs struggle to upgrade equipment regularly. Options like leasing instruments short-term, sharing costs among departments, utilizing company donations, and incorporating student personal devices help provide access to current tools when budgets are tight.

Q: Should humanities courses be incorporated into engineering programs?

A: Ethics, writing, communication, business, and social science electives play a complementary role to technical training in most programs. However, equipment labs and project time should still dominate curriculums. Striking an optimal balance of technical and non-technical courses remains a challenge.

Conclusion

Hands-on learning using the same equipment students will encounter in their engineering careers after graduation is an essential component of technical education. Operating machines, running experiments, building prototypes, and gaining first-hand experience accelerates the development of both hard skills and engineering judgment. While expanding access to equipment poses challenges for schools constrained by budgets, lab space, safety demands, and outdated technology, fostering partnerships with private industry could provide creative solutions. Ultimately, equipment mastery underpins students’ transition from academia to becoming capable engineering professionals. Keeping hands-on training at the core of engineering teaching philosophy ensures graduates will thrive and lead innovation in the future.

Tags: engineering education, engineering students, equipmentin engineering, hands on learning, stem education

Leave a Reply