In this article, we’ll examine the YET analysis, Predictive maintenance, Profit-per-Hour maximization of manufacturing analytics, and their cost. Then, we’ll explore the benefits and drawbacks of each. Finally, we’ll also discuss some of the pitfalls and common mistakes of What is Manufacturing Analytics? | Knime about. Keep in mind that there are many benefits to embracing analytics in manufacturing.

YET analysis

Using YET analysis in manufacturing analytics to optimize production has several advantages:

- It can identify areas for improvement in operational efficiency and reduce energy requirements. A single small change to a process can dramatically increase profitability.

- Even a tiny increase in efficiency can improve earnings before interest and tax.

- The data generated during the manufacturing process can help quality assurance engineers identify inconsistencies and deviations from the standard.

Tracking such metrics will help them predict quality issues before they occur.

Predictive maintenance is a powerful way to understand a plant’s capacity and how many units it can produce in one cycle. YET analyses can help reduce energy consumption and improve yields. Profit-per-hour maximization can help optimize the production process by scrutinizing thousands of parameters. These tools can maximize production efficiency by identifying the optimal number of units produced in a specific period.

Predictive maintenance

One of the fastest-growing industries, oil, and gas, is rapidly adopting predictive maintenance. These industries collect vast amounts of data from wireless sensors and equipment, making it challenging to keep track of the condition of these assets. By analyzing this data, manufacturers can reduce the likelihood of a machine breaking down or becoming unreliable. Predictive maintenance in oil and gas operations has proven highly effective in reducing unplanned downtime and increasing production.

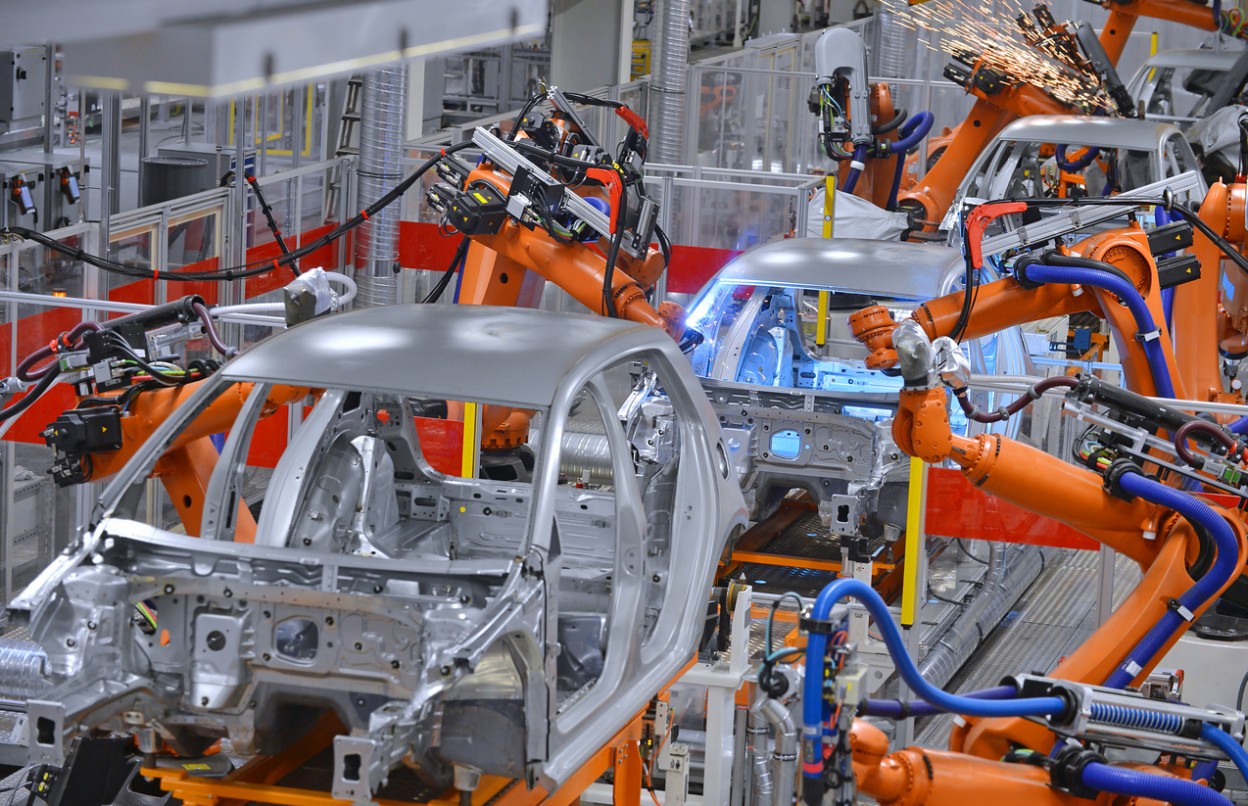

Predictive maintenance uses machine learning, a process that uses sensor data to determine the expected behavior of a piece of equipment. This technique can also detect anomalies, but it requires good quality data. One of the most important aspects of predictive maintenance is a computerized maintenance management system (CMMS), which creates work orders for maintenance technicians when anomalies are detected. Predictive maintenance can also use condition monitoring devices to track the condition of any asset.

Profit-per-Hour maximization

The goal of profit-per-hour maximization in manufacturing is to increase profits per unit of production time. Profit-per-hour analytics can help manufacturers improve productivity and minimize costs by analyzing data and examining conditions in production processes and using real-time data, profit-per-hour analyses based on the optimal operating conditions of manufacturing systems. Advanced analytics solutions provide an unprecedented level of operational insight. They offer a single, actionable source of truth for decision-making. Profit Velocity empowers decision-makers with powerful insights by identifying the fastest money-making products, customers, machines, and plants. Profit-per-Hour analysis can inform changes in customer and product mix. Profit-per-Hour maximization is possible and necessary for the long-term survival of a manufacturer.

Advanced analytics solutions enable manufacturers to resolve seemingly impossible problems. They uncover hidden bottlenecks and unprofitable production lines. By combining disparate data sets, analytics solutions help manufacturing professionals gain unprecedented insight into their operations. In optimizing production processes, minor decisions can dramatically affect profitability. By leveraging the power of analytics, manufacturers can enhance profitability and maximize productivity by identifying and eliminating unprofitable product lines and processes.

Cost of manufacturing analytics

Traditionally, manufacturers have been unable to harness end-to-end manufacturing data, which is critical for optimizing outputs and increasing profitability. Instead, they have been reliant on expensive tools that collect information from machines and operators but are limited in their ability to analyze it. Unfortunately, this data collection method is no longer feasible in a highly competitive environment, and manufacturers need complete visibility into the entire process to make informed decisions and optimize outputs.

Manufacturing analytics can reveal patterns in failure and lead to improved production. Manufacturing companies develop their products with future demand in mind. However, most businesses make their forecasts based on historical values, which are not always accurate. Manufacturing analytics allows them to predict the future direction and determine improvements to production problems. By applying these insights, manufacturers can improve their production efficiency and eliminate downtime. This approach has several advantages. It also provides a strong ROI argument for businesses.

Leave a Reply