A Deep Discussion of Impeller vs Propeller: Spinning Things That Move Fluids

How do machines and devices move fluids around? Well, you’ve come to the right place. In this post, we’re going to nerd out over impeller vs propeller two types of spinning components that make the world go ’round.

Now, I know these aren’t the sexiest topics. My friend’s eyes tend to glaze over when I start rambling about radial flow impellers or marine propeller designs. But trust me – once you understand how these unsung heroes work, you gain a whole new appreciation for things like ventilation systems, outboard motors, and even the water flowing from your faucet.

So, what exactly are impellers and propellers? Both are rotating devices that are used to move fluids. However, they operate differently and have distinct applications. We’ll unpack all of that here.

Impeller Vs Propeller at a Glance

First up, let’s see the key differences between impellers and propellers:

| Feature | Impeller | Propeller |

| Enclosed in a housing? | Yes | No |

| Vanes or blades? | Vanes | Blades |

| Draws in fluid or pushes against fluid? | Draws in fluid | Pushes against fluid |

| Applications | Pumps, mixers, compressors, turbines | Marine propulsion, aerospace propulsion, wind turbines |

What is an Impeller?

An impeller is a rotating component that is typically enclosed inside a housing or casing. The housing is there for a reason – to concentrate the impeller’s work in a specific direction.

Impellers have curved vanes or blades attached to a central hub. The vanes are specially shaped to draw fluid into the center of the impeller when it spins. The fluid gets accelerated outward by centrifugal force.

So in essence, an impeller moves fluid by pulling it in and flinging it out. This creates flow and pressure for various uses.

You’ll find impellers hard at work in all kinds of machines:

- Pumps – Impellers pressurize and transport fluids. Your home water pump has one.

- Mixers – Impellers blend liquids or gases. Think paint mixers or chemical reactor vessels.

- Compressors – Impellers squeeze gases into a smaller volume. Your refrigerator uses a compressor impeller.

- Turbines – Impellers extract energy from pressurized fluids. Hydroelectric turbines contain them.

Key features of impellers

- Enclosed in a housing – The casing contains the fluid flow.

- Curved vanes – These specially shaped blades pull in and accelerate the fluid.

- Creates flow and pressure – The spinning action moves the fluid through the housing.

- Used in pumps, mixers, compressors, and turbines – Impellers have wide industrial applications.

Now that we understand what impellers are all about, let’s shift gears and talk propellers.

What is a Propeller?

If an impeller operates inside a housing, then a propeller is the opposite. Propellers are rotating devices that are open to the surrounding fluid.

You’re probably most familiar with marine propellers on boats and aircraft propellers on planes. But propellers are used in other applications too.

Propellers consist of two or more blades attached to a central hub. The blades are angled and shaped to create forward thrust as they spin. The propeller pushes back on the fluid, generating rotational force that propels the craft forward.

Key facts about propellers

- Exposed to surrounding fluid – Propellers operate openly rather than in a casing.

- Blades push fluid backward – The angle and curvature of the blades provide forward thrust.

- Creates thrust for propulsion – The pushing force propels vessels through water or air.

- Used on boats, planes, helicopters, wind turbines – Propellers have widespread transportation uses.

So, in summary:

- Impellers pull fluid in, propellers push fluid out.

- Impellers use enclosed housings, propellers operate freely.

- Impellers build pressure, propellers provide propulsion.

This gives you a basic overview of how impellers and propellers work. Now, let’s dig deeper and explore some of the technical nuances.

Comparing Impeller and Propeller Designs: Impeller vs Propeller

When engineers set out to design impellers and propellers, they have to account for the specific application. An impeller that works well in a mixer may not perform well inside a compressor. And you certainly can’t swap a boat propeller for an airplane!

While they both move fluids, impellers and propellers have vastly different design requirements.

Impeller Types and Design Factors

One of the first decisions when designing an impeller is whether it will be a centrifugal or axial style:

- Centrifugal impellers have fan-like blades that curve outward. They’re well-suited for low-viscosity fluids like water.

- Axial impellers have straight blades that run parallel to the shaft. They excel at handling high-viscosity fluids like oils or slurries.

Other impeller design considerations include:

- Number of vanes – More vanes provide greater pressure but lower efficiency.

- Vane shape – Curved and angled vanes enhance performance.

- Balancing – Impellers spin at high speeds and must be balanced.

- Strength – Impeller materials must withstand force and wear.

- Housing design – The casing shape affects fluid flow and pressure.

- Bearings – Friction-reducing bearings help efficiency and life span.

- Seals – Seals prevent fluid from leaking out of the housing.

Impellers are truly engineering marvels! Tiny design tweaks can impact performance, efficiency, and durability. Engineers use physics, materials science, and computational fluid dynamics software to optimize impellers.

Propeller Types and Design Factors

Propellers may look basic, but their design is complex. Marine engineers must consider vessel speed, engine power, and seawater resistance. For aircraft, weight, noise, vibration, and other aerodynamic issues come into play.

Some common propeller types:

- Fixed pitch – Simple and inexpensive but less efficient.

- Controllable pitch – Blades can change the angle for optimum thrust.

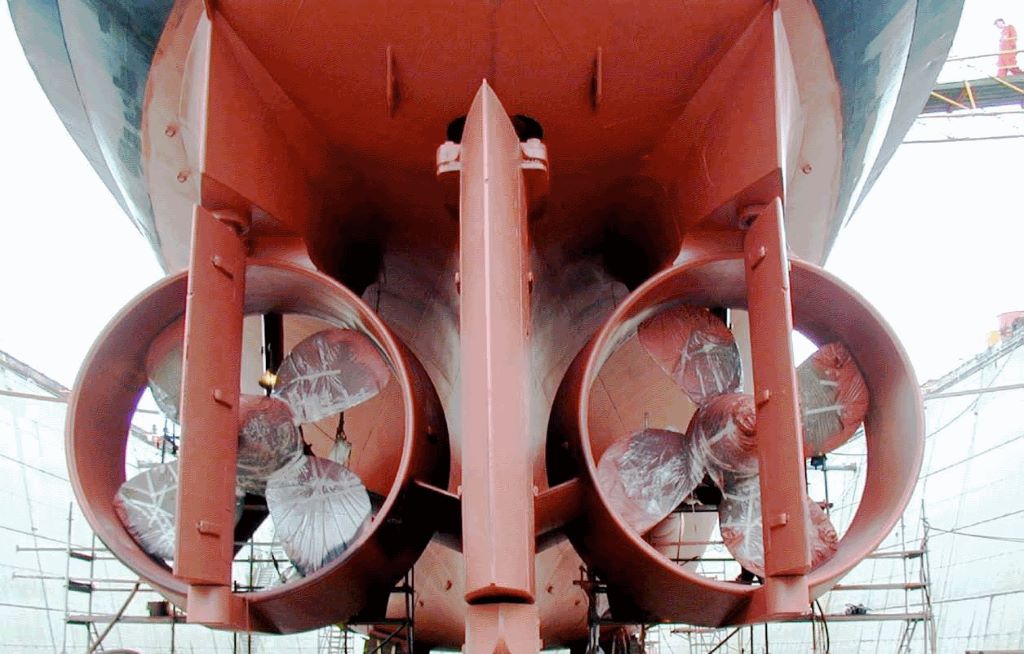

- Ducted – A nozzle around the propeller focuses thrust.

Other propeller design considerations:

- Number of blades – More blades spread out thrust over a larger area.

- Blade shape – Advanced propellers have twisted, tapered blades.

- Blade materials – Strong, lightweight alloys improve efficiency.

- Gearing – Gearboxes allow optimum prop speed versus engine speed.

- Direction – Most propellers are right-handed, but some vessels use left-handed.

- Noise and vibration – Propeller balancing minimizes these.

Even minor propeller adjustments can improve speed, fuel economy, and noise levels. Whether it’s a houseboat or a jumbo jet, propeller performance matters!

Impeller and Propeller Materials

We’ve covered the physics of impellers and propellers. But what about the physical materials they are made from?

The material choice comes down to properties like:

- Strength – Withstand high rotation speeds and fluid forces.

- Stiffness – Resist deformation under load.

- Hardness – Wear resistance for long service life.

- Weight – Lightness improves efficiency and allows faster speeds.

- Corrosion resistance – Fluids can be highly acidic or alkaline.

- Cost – Striking the right balance of performance and affordability.

Common materials used

Impellers:

- Metals – Stainless steel, carbon steel, brass, aluminum alloys

- Plastics – Thermoplastics like nylon, polycarbonate, PVC, and polypropylene

- Composites – Glass fiber or carbon fiber reinforced resins

Propellers:

- Metals – Stainless steel, aluminum alloys, titanium alloys, nickel alloys

- Composites – Carbon fiber provides an excellent strength-to-weight ratio

Of course, exotic materials like beryllium copper allow premium performance for specialized applications like aircraft carriers.

But generally, engineers select affordable, readily available materials that can withstand the operating environment. With good maintenance, most impellers and propellers have long, reliable service lives.

Comparing Impellers and Propellers in Action

By now you should have a solid grasp of what impellers and propellers are, how they work, and why they are designed differently. To drive the concepts home, let’s compare them side-by-side on some real-world equipment.

First, take a look under the hood of your car. The air conditioning compressor contains an impeller in a sealed housing. It spins at high speed to draw in refrigerant vapor and compress it, allowing the A/C system to function. Your car certainly couldn’t use an open propeller for this!

On your outboard motorboat, an open propeller provides thrust by pushing back on the water. The propeller operates freely in the lake or sea. Its twisted blades allow it to work efficiently across a range of speeds. An enclosed impeller could never generate enough propulsive force.

When you get on an airplane, consider the giant turbine engines hanging under the wings. They contain multistage axial and centrifugal impellers that compress air to extremely high pressures. Far downstream, you’ll see an open propeller or enclosed fan providing the actual engine thrust. This demonstrates how impellers vs propellers work together in complex machines, showcasing the crucial distinction between impeller-driven compression and propeller-driven propulsion.

Hopefully, these examples illustrate when it makes sense to use an impeller versus a propeller in real-world systems. Although they look vaguely similar, the design and physics are different.

Impeller vs Propeller Maintenance

Before we wrap up, a word on taking care of your impellers and propellers. After all, these components see a lot of wear and tear over time.

For impellers, regular maintenance checks are a must. Warning signs include:

- Leaks around the casing – Can indicate worn casing rings or shaft seals.

- Unusual noise or vibration – Suggests mechanical damage or erosion.

- Loss of pressure or flow – Often caused by eroded or fouled vanes.

- Overheating – May signal bearing wear or clogged flow passages.

Routine inspections, oil changes, and cleaning of fluid passageways help prevent many impeller failures. Replacing worn bearings and seals as needed prevents more serious damage.

With propellers, technicians focus on:

- Cracks in blades – Can rapidly enlarge and lead to failure.

- Blade surface damage – Caused by debris strikes or corrosion.

- Gearbox wear – Inspected through oil analysis and vibration monitoring.

- Balance – Propellers undergo dynamic balancing to counter vibration caused by imbalance.

Well-maintained impellers and propellers are happy impellers and propellers!

Example of the Difference Between Impeller and Propeller

Here are some examples of the differences between impellers and propellers:

Impeller

- Impeller in a pump: An impeller is used in a pump to increase the pressure of a fluid. It does this by drawing in fluid and accelerating it. The vanes or blades in the impeller are designed to efficiently move the fluid.

Propeller

- Propeller on a boat: A propeller propels a boat through the water. It does this by pushing against the water with its blades. The propeller is typically located at the stern of the boat and is connected to the engine by a shaft.

Other examples

- Impeller in a food processor: An impeller is also used in a food processor to chop and blend food. It does this by spinning rapidly and cutting the food into smaller pieces.

- Propeller on an airplane: A propeller is also used on an airplane to propel it through the air. It does this by pushing against the air with its blades. A shaft connects the engine to the propeller, typically positioned at the front of the airplane.

FAQs

Q: What’s the main difference between an impeller and a propeller?

A: The main difference is that impellers operate inside a housing to create flow and pressure. Propellers operate openly to provide propulsive thrust.

Q: Where would you find an impeller, but not a propeller?

A: Machines like pumps, compressors, and mixers use impellers. You would never find a propeller in those applications.

Q: Where would you find a propeller, but not an impeller?

A: Boats, airplanes, and helicopters use propellers for transportation. You would never find an exposed impeller used for propulsion.

Q: Can a propeller work underwater?

A: Yes, marine propellers are designed specifically for underwater operation. The blade shape is optimized to provide thrust through water.

Q: Which is more efficient, an impeller or a propeller?

A: It depends on the application. Impellers can be highly efficient for heat pumps, turbines, etc. Propellers are more efficient for marine and aircraft propulsion. There is no universally “more efficient” choice.

Final Thoughts

Rotating fluid devices use impellers and propellers as important mechanical components. While they may often go unsung, they play a crucial role in everything from pumps to turbines.

If you’re looking to learn more about these fascinating pieces of machinery, don’t hesitate to reach out. How hard is mechanical engineering? Whether you have questions or are simply looking for more in-depth information, I’m here to help. If you found this information on impeller vs propeller useful, be sure to share it with anyone else in your life who might be interested, as the difficulty of mechanical engineering often depends on one’s dedication and willingness to tackle complex challenges.

Leave a Reply