You probably first encountered vacuum conveying at school through the straw in your milk carton. Once you realised you could either suck or blow, you pretty much got it.

Of course, in industrial settings, the equipment is considerably more sophisticated and bigger. It’s also used for moving a wide variety of materials, some of which need protecting from the environment – or the environment from them.

Hygienic containment

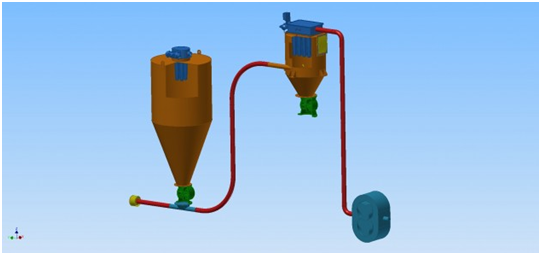

Vacuum conveying is ideal for moving large quantities of material while minimising atmospheric leakage. A vacuum conveyor uses an exhauster near the receiver to create airflow. It can be regulated for continuous flow or deliver timed batches, whichever suits the receiving process or the arrival of supplies. The distances vary between a few feet and many hundreds of metres, and one of the great advantages of a pneumatic system is that it is easily routed around existing plant machinery and involves less equipment to maintain or break down.

Vacuum systems are better suited to lower throughput and shorter distances than positive pressure conveying, but in both cases, controlling equipment is focused at the ends. Varieties of feeder and receiver mechanisms exist, but control can often be centralised at a single panel or integrated into a robotic system. Multiple delivery routes are possible, although multiple points of origin are easier with vacuum systems and multiple points of delivery with positive pressure.

Flow density

Pneumatic conveying is further divided into “dilute” and “dense” phase options. Dilute is the term used when there is a high ratio of flowing air lifting a cargo of light particles such as flour, sugar or chemical powders. In dense phase, the air flow is gentler and the material is rolled through at a denser ratio. The latter is often chosen for materials that are delicate or prone to separation.

A pneumatic conveying consultant will advise you whether to use vacuum or pressure, dilute or dense phase, and the numerous delivery and receiver mechanisms like those at http://www.aptech.uk.com/pneumatic-conveying/vacuum-conveying/). A very good guide to the density of common foodstuffs and industrial materials can be found here: http://www.bulksolidsflow.com.au/free_programs/bulk_density/bulk_density.html.

Your consultant will precisely calculate the pressures and pipeline dimensions required to move your material based on its bulk density, your plant throughput, and the chosen route. Some materials behave in unusual ways, but this, too, can be anticipated.

Leave a Reply